Understanding Stereolithography: Revolutionizing 3D Printing

Stereolithography, often abbreviated as SLA, is a groundbreaking technology that has transformed the landscape of 3D printing. With its unparalleled precision and ability to create intricate designs, stereolithography is at the forefront of manufacturing and design processes across various industries. In this article, we will delve into the fundamentals of stereolithography, explore its applications, discuss its advantages, and look ahead to its future in the ever-evolving world of 3D printing.

The Basics of Stereolithography

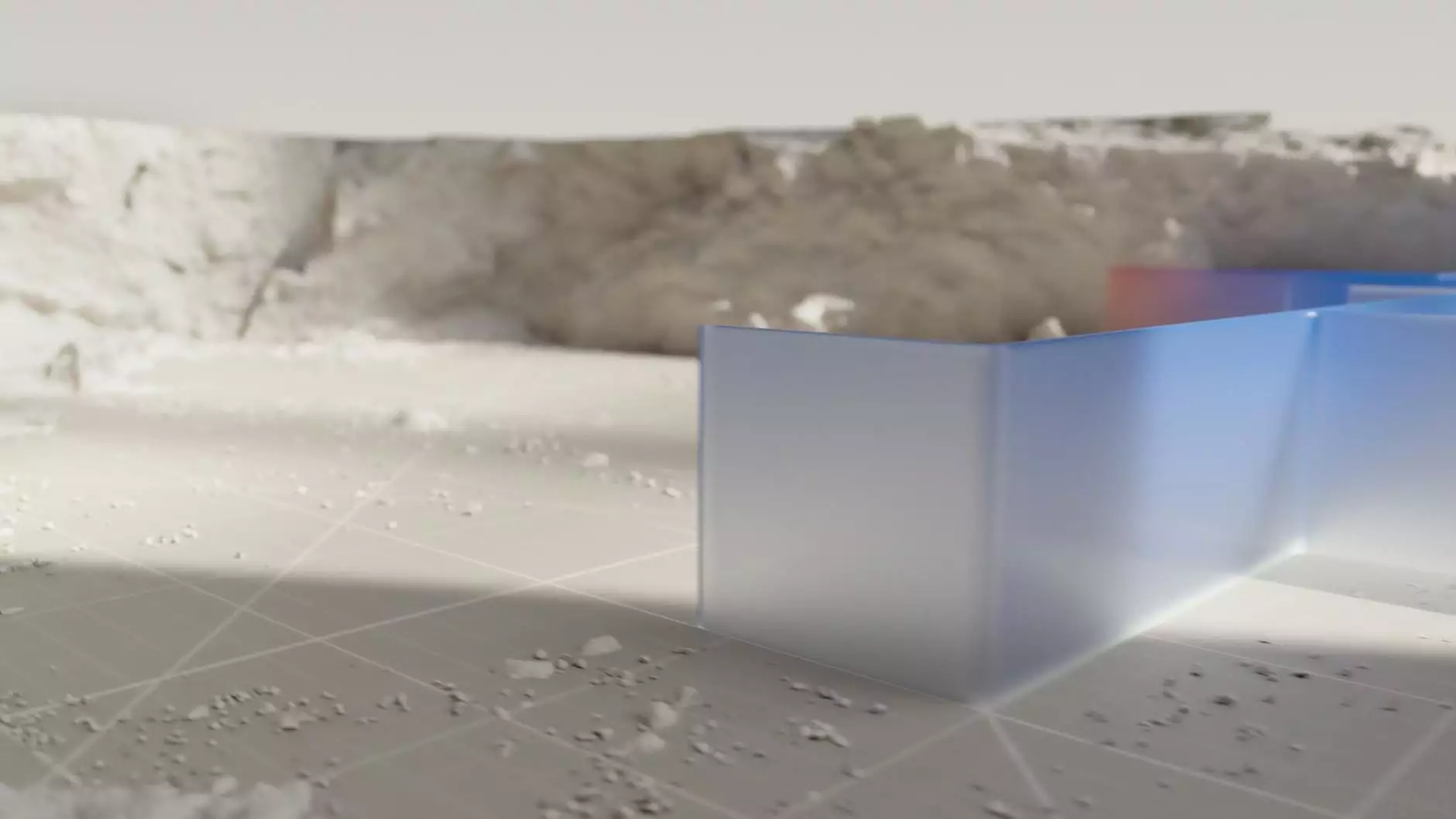

Stereolithography was the first commercial technology for 3D printing, developed in the 1980s by Chuck Hull. The technology works by curing a liquid resin into solid plastic through a layer-by-layer process using ultraviolet (UV) light. This method allows for highly detailed and complex structures to be produced

How Does Stereolithography Work?

The process of stereolithography involves several key steps:

- Design Creation: Using computer-aided design (CAD) software, a 3D model is created.

- Slicing the Model: The 3D model is divided into thin horizontal layers using slicing software.

- Resin Preparation: A liquid photopolymer resin is poured into a vat.

- Layer-by-Layer Curing: A UV laser selectively cures the resin, solidifying it layer by layer, until the object is complete.

- Post-processing: The finished part is removed from the vat, and any excess resin is cleaned off, often requiring further curing under UV light.

Applications of Stereolithography

Stereolithography is not limited to a specific industry; its applications span numerous fields:

1. Prototyping

Companies utilize stereolithography to produce accurate prototypes quickly. The ability to create highly detailed and functional prototypes makes it an invaluable tool in product development. Whether it's for consumer goods, automotive parts, or electronics, the SLA process allows engineers to test and validate designs before moving to production.

2. Medical Applications

The medical industry has embraced stereolithography for creating custom implants, prosthetics, and even anatomical models for surgical planning. The precision of stereolithography enables the production of patient-specific solutions that enhance surgical outcomes.

3. Aerospace and Automotive Industries

In industries where weight and design complexity are critical, such as aerospace and automotive, stereolithography plays a vital role. Lightweight structures can be fabricated that meet stringent regulatory standards while optimizing performance.

4. Jewelry Design

SLA technology has revolutionized jewelry making, allowing designers to produce intricate patterns and detailed designs that were previously impossible with traditional methods. The rapid turnaround time also allows for rapid changes and customization.

Benefits of Using Stereolithography

As one of the leading technologies in the 3D printing sector, stereolithography offers numerous benefits:

- High Precision: The layer-by-layer approach allows for extremely high detail and accuracy in the final product.

- Complex Geometries: Stereolithography can produce complex shapes that are difficult or impossible to create with traditional manufacturing processes.

- Speed: The rapid prototyping capabilities reduce the time from concept to production, allowing for faster iterations.

- Material Variety: A range of photopolymer resins is available, offering various properties such as flexibility, strength, and transparency.

Challenges and Limitations of Stereolithography

While stereolithography boasts many advantages, it is essential to consider the challenges that accompany this technology:

- Material Costs: Photopolymer resins can be more expensive than other 3D printing materials.

- Post-Processing: The parts often require post-processing, which can be time-consuming and complicate the workflow.

- UV Sensitivity: The finished products are sensitive to UV light and may degrade over time if not properly protected.

The Future of Stereolithography in 3D Printing

The future of stereolithography looks promising, with continuous advancements in technology and materials. Some of the anticipated developments include:

1. Improved Materials

Advancements in resin technology are expected to produce stronger, more versatile materials, expanding the range of applications significantly.

2. Faster Printing Technologies

Emerging technologies aim to reduce print times even further, enhancing productivity and efficiency for industrial applications.

3. Integration with Other Technologies

As industries move towards digital manufacturing, integrating stereolithography with techniques like generative design and machine learning will likely unlock new potential for innovative designs.

Conclusion

In summary, stereolithography is a revolutionary technology that has set a benchmark for precision, speed, and versatility in the 3D printing industry. Its numerous applications, especially in sectors like medical, aerospace, and automotive, underline its significance in modern manufacturing. As technology progresses, we can expect stereolithography to evolve, driving further innovation and opening new avenues for design and production.

Learn More About Stereolithography

For businesses looking to harness the power of stereolithography, Infotron offers cutting-edge 3D printing solutions tailored to meet your needs. Visit infotron.com.tr to explore our range of services and how we can help you innovate in your industry.