Understanding the Parts of the Crankshaft in Diesel Engines

The crankshaft is a critical component in diesel engines, acting as the heart that converts linear motion into rotational motion. The performance and efficiency of any diesel engine largely depend on the quality and functionality of its crankshaft parts. In this comprehensive guide, we will delve into the parts of the crankshaft, their functions, and the importance of proper maintenance and replacement when necessary.

What is a Crankshaft?

The crankshaft is a long, cylindrical component made of high-strength steel or iron. It operates within the engine block, converting the up-and-down (reciprocating) movement of the engine's pistons into rotary motion that ultimately powers the vehicle's drivetrain. The efficiency of this process depends on the various parts of the crankshaft, each serving a specific function.

Key Parts of the Crankshaft

Understanding the parts of the crankshaft is essential for anyone involved in the maintenance or repair of diesel engines. Below are the primary components of a crankshaft and their significance.

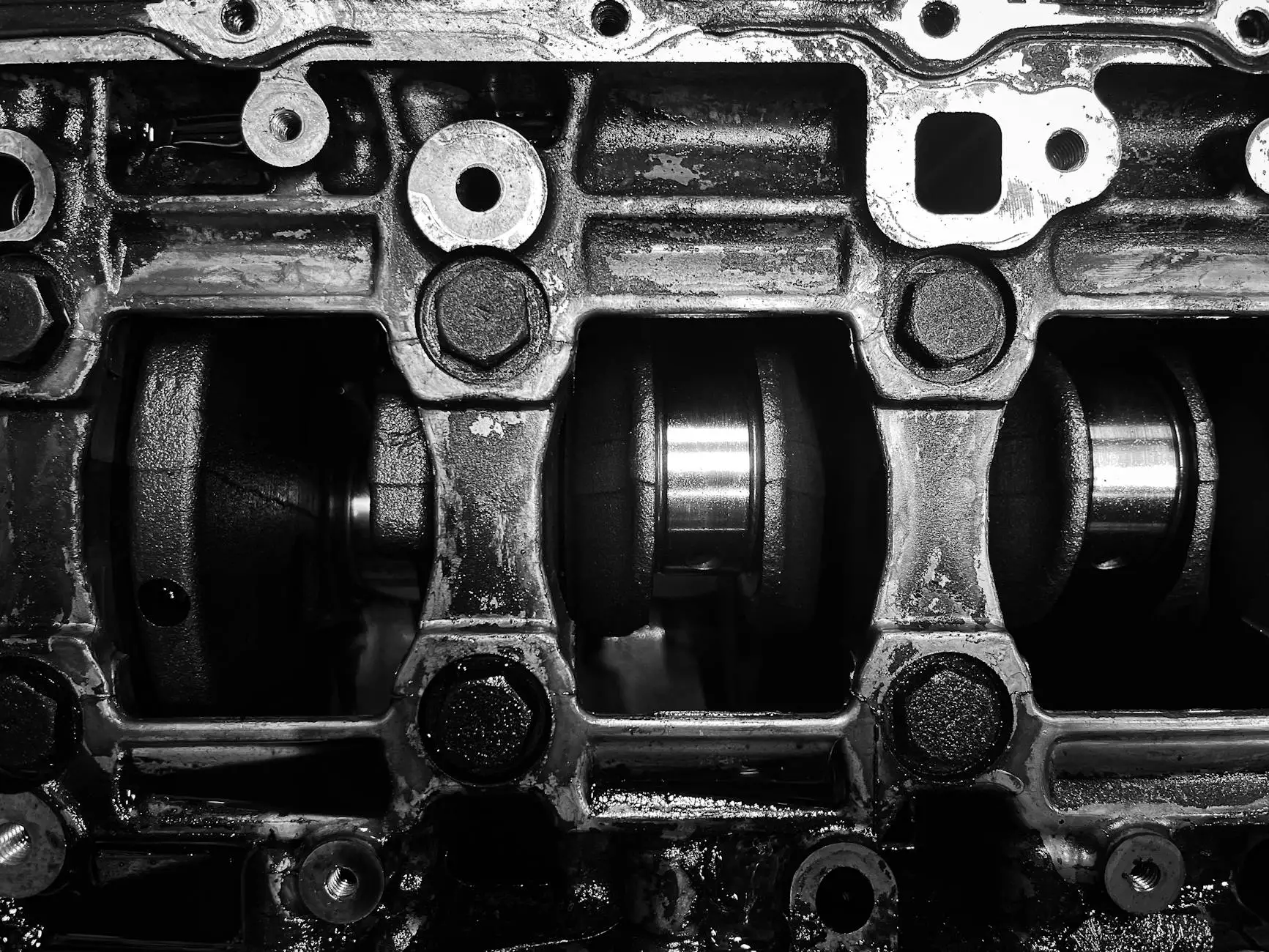

1. Main Journals

The main journals are the sections of the crankshaft that rotate within the engine block, supported by main bearings. They play a pivotal role in maintaining the crankshaft's alignment and stability during operation. Their smooth surface is crucial for minimizing friction, thereby enhancing the engine's overall efficiency.

2. Rod Journals

The rod journals connect to the connecting rods of the engine. As the crankshaft rotates, these journals enable the transfer of power from the crankshaft to the pistons. Proper alignment and condition of the rod journals are vital for optimal engine performance.

3. Crank Pins

Crank pins are offset from the main axis of the crankshaft and serve as the pivot points for the connecting rods. This unique design allows the crankshaft to convert the linear motion of the pistons into rotational motion. The durability of the crank pins is crucial, as they endure significant stress during engine operation.

4. Counterweights

Counterweights are essential for balancing the crankshaft and counteracting the forces produced during operation. Without them, the engine would experience vibrations that could lead to premature wear and failure. The design and placement of counterweights are critical in minimizing these vibrations.

5. Flywheel

The flywheel, often bolted directly to the crankshaft, plays a significant role in smoothing out the power delivery from the engine. It stores rotational energy, providing stability and helping to maintain consistent engine speed regardless of load conditions.

The Importance of Quality Crankshaft Parts

Investing in high-quality parts of the crankshaft is crucial for the longevity and performance of a diesel engine. Here are several reasons why quality matters:

- Durability: High-quality materials withstand the stresses and heat generated within the engine, reducing the likelihood of failure.

- Performance: Quality crankshaft parts ensure smooth operation, which directly impacts fuel efficiency and overall engine power.

- Maintenance: Using superior parts minimizes the need for frequent replacements and repairs, saving both time and resources.

- Compatibility: Quality parts are designed to meet OEM specifications, ensuring a perfect fit in your diesel engine.

Common Problems with Crankshaft Parts

Understanding potential issues with the parts of the crankshaft is essential for effective maintenance. Here are some common problems:

1. Wear and Tear

Over time, the main and rod journals may experience wear due to constant friction with the bearings. This can lead to decreased efficiency and increased oil consumption.

2. Crankshaft Misalignment

Improper installation or worn engine mounts may lead to misalignment, causing uneven wear and balance issues that can affect engine performance.

3. Crankshaft Damage

Crankshafts can suffer from various forms of damage due to inadequate lubrication, overheating, or excessive loading. Cracks or bends in the crankshaft can necessitate a full replacement.

Maintenance Tips for Crankshaft Parts

Proper maintenance of crankshaft components is crucial in prolonging engine life. Here are some essential tips:

- Regular Oil Changes: Keeping the engine oil clean and at the correct levels reduces friction and helps maintain a smooth operation.

- Monitor Engine Temperature: Overheating can lead to crankshaft issues, so ensuring the cooling system functions correctly is vital.

- Inspect for Wear: Routine inspections can detect early signs of wear, allowing for timely replacements before major failures occur.

- Use Quality Parts: Always opt for high-quality replacement parts that meet OEM standards to ensure compatibility and performance.

The Role of Diesel Engine Part Suppliers

Choosing the right supplier for diesel engine parts, including parts of the crankshaft, is vital for ensuring you get high-quality products. Here’s what to look for in a supplier:

- Reputation: Look for suppliers like client-diesel.com with a solid track record and positive customer feedback.

- Product Range: A diverse selection of parts ensures that you can find everything you need in one place.

- Expertise: Suppliers that offer expert advice can help you make informed decisions regarding part selection and maintenance.

- Warranty: A good warranty on parts is a reflection of a supplier’s confidence in the quality of their products.

Conclusion

The parts of the crankshaft play a crucial role in the overall functioning of diesel engines. From ensuring effective power delivery to maintaining engine balance, each component must work harmoniously for optimal performance. Regular maintenance and using high-quality replacement parts like those offered at client-diesel.com can significantly enhance the longevity and efficiency of your diesel engine. By prioritizing quality and knowledgeable suppliers, you can ensure that your engine remains reliable and efficient for years to come.